Adhesive bonding primer is a fundamental component in the world of adhesives, ensuring that surfaces are prepared and ready for a strong, durable bond.

Adhesive bonding primer is a fundamental component in the world of adhesives, ensuring that surfaces are prepared and ready for a strong, durable bond. But what exactly is adhesive bonding primer, and why is it so important? In this article, we’ll explore the purpose and benefits of adhesive bonding primer, as well as some common applications and tips for using it effectively.

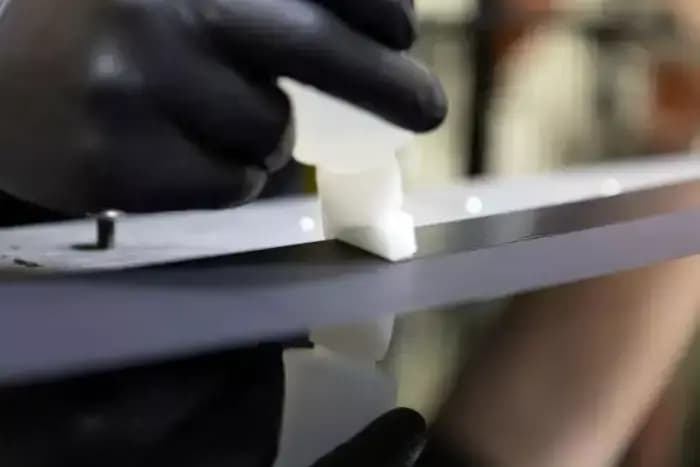

Adhesive bonding primer is a pre-treatment solution that is applied to surfaces before bonding with an adhesive. This solution helps to improve adhesion by modifying the surface characteristics, increasing the surface energy, and promoting chemical bonding between the adhesive and the substrate (the material being bonded). In other words, it serves as an intermediary layer that ensures a strong, long-lasting bond between two surfaces.

Adhesive bonding primer is critical for several reasons:

Improved Adhesion: Some materials have low surface energy, which means they don’t bond well with adhesives. Primers increase the surface energy, allowing for better bonding between the adhesive and the substrate.

Enhanced Durability: When surfaces are adequately prepared with a bonding primer, the resulting bond is stronger and more resistant to environmental factors such as moisture, temperature fluctuations and chemical exposure.

Reduced Surface Contaminants: Bonding primers can help remove or neutralize contaminants that might be present on a substrate, preventing them from interfering with the bond.

Compatibility: Primers can ensure compatibility between the adhesive and the substrate, preventing adverse reactions or weakening of the bond over time.

Adhesive bonding primers are used in a wide range of industries and applications, including:

Automotive: In the automotive industry, adhesive bonding primers are used to bond components like windshields, body panels and trim pieces, ensuring a strong bond and increased durability.

Aerospace: Primers are crucial in aerospace applications where high-strength bonds are required for the assembly of aircraft components, such as wings, fuselage and interior fittings.

Construction: In construction, adhesive bonding primers are used to bond various materials like wood, concrete and metal, providing a lasting bond for structural components.

Electronics: Adhesive bonding primers are used in electronic applications to bond elements, such as circuit boards and various electronic devices, establishing reliable performance and longevity.

Choosing the right adhesive bonding primer for your project is crucial for achieving a lasting bond. There are several types of primers available, each designed for specific applications and materials. Here are a few of the main types of bonding primers and their distinct advantages:

Epoxy-based primers are popular due to their versatility and excellent adhesion properties. They consist of two components—a resin and a hardener—that, when mixed, create a chemical reaction resulting in a powerful bond. Epoxy primers are suitable for a wide range of materials, including metals, plastics, ceramics and wood.

Advantages

Exceptional bond strength

High resistance to chemicals, moisture and temperature fluctuations

Versatility across various materials and applications

Applications

Automotive and aerospace components

Construction and industrial equipment

Marine applications

Acrylic-based primers are known for their fast curing times and strong adhesion properties, making them ideal for time-sensitive projects. These primers are typically one-component and can be applied in thinner layers compared to epoxy-based primers. Acrylic primers are well-suited for bonding plastics, metals and glass.

Advantages:

Fast curing times

Good bond strength and durability

Easy application and handling

Applications:

Electronics and consumer goods

Automotive and transportation components

Signage and display fabrication

Polyurethane-based primers are flexible, offering excellent elongation and impact resistance. They are especially suitable for applications where the bonded materials are subject to movement or stress. These primers are commonly used with materials like rubber, plastics and metals.Advantages:

Flexibility and impact resistance

Good adhesion to various substrates

Resistance to abrasion and wear

Applications:

Automotive interior and exterior components

Flexible joints and seals

Sports equipment and footwear

Understanding the different types of bonding primers and their unique properties is essential for selecting the best primer for your specific project.

Go back